OEM 3/4 Flutes End yokusila kunye Shank Straight kunye Wave Cutting Edges

Isicelo

I-3 Flutes End Mills kunye ne-Straight Shank kunye ne-Wave Cutting Edges ilungele ukulungiswa kwe-alloys ye-aluminium, kunye ne-side machining, i-step machining, kunye ne-right angle groove machining.Kwaye i-4 Flutes End mills kunye ne-Straight Shank kunye ne-Wave Cutting Edges ifanelekile ukucutshungulwa kwe-carbon steel, i-alloy steel, i-iron cast, i-ductile iron, intsimbi yangaphambili, i-quenched steel (~ 40HRC) l, njl. ukusetyenzwa kwenyathelo, kunye ne-engile ye-groove processing.

Iinkcukacha

Imathiriyeli ekrwada yokuvelisa i-3 flutes end mill yi-UK10, enezixhobo zokusika ezifumaneka kububanzi obusuka kwi-6 mm ukuya kwi-20 mm, kunye nobude besixhobo bubonke ukusuka kwi-50 mm ukuya kwi-100 mm.I-angle ejikelezayo ye-clutter yi-45 degrees.

Imathiriyeli ekrwada yokuvelisa i-4 flutes end mill yi-UK30, eqatywe nge-ATN.I-angle ye-spiral ye-clutter yi-degrees ezingama-30, kwaye ububanzi bangaphandle be-milling cutter bufumaneka kwi-6 mm ukuya kwi-20 mm.Ubude obupheleleyo bomsiki bungama-50 mm ukuya kwi-100 mm.

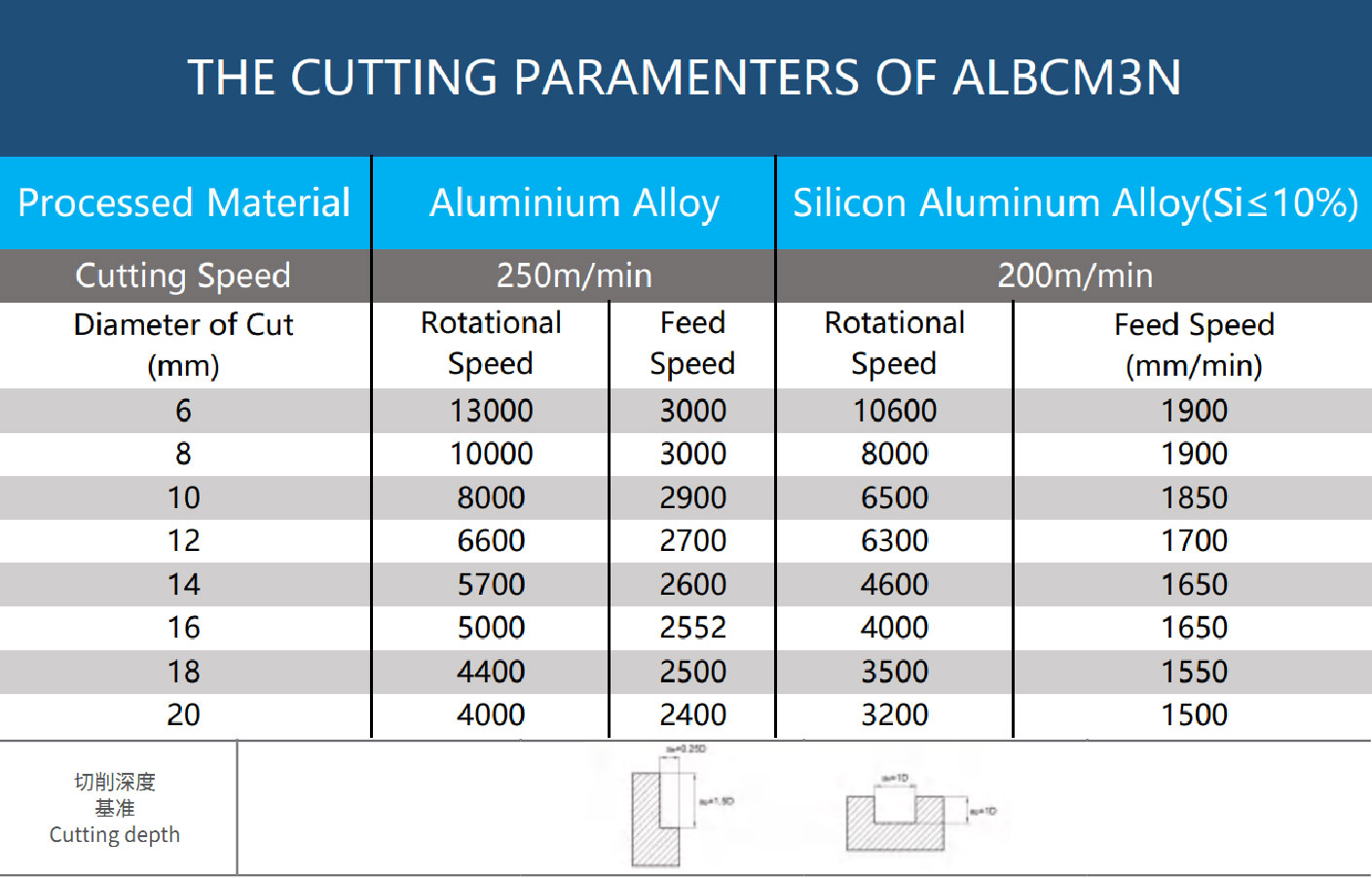

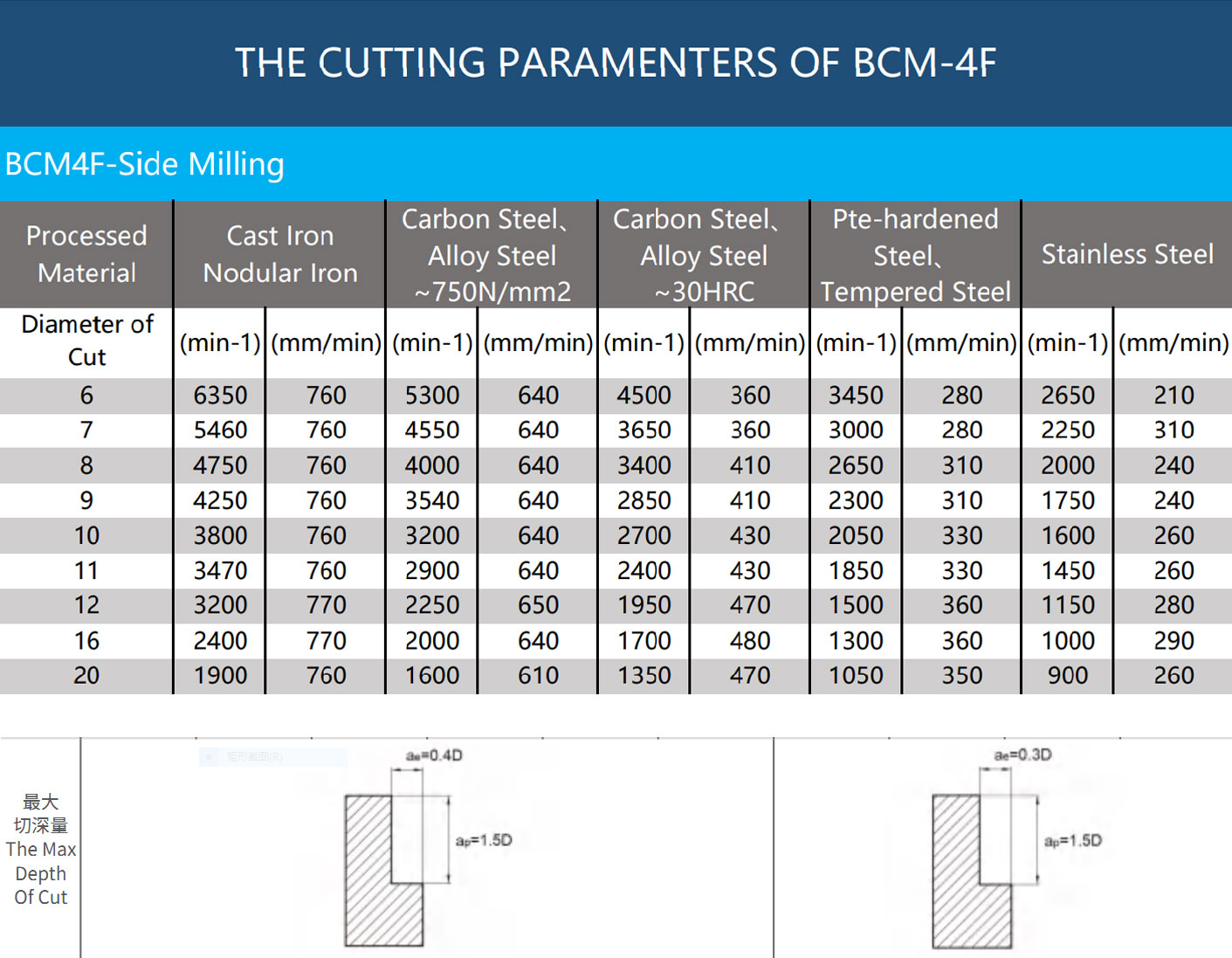

Iimpawu zokusika ze-ALBCM3N / BCM4F

1. Xa ubunzulu bokusika buncinci, isantya sokujikeleza kunye nesantya sokutya sinokuphuculwa ngakumbi

2. Ulwelo lokusika olunyibilikayo lwamanzi luyacetyiswa

3. Ukugaya umphezulu kuyacetyiswa

4 .Kwimeko yomatshini kunye ne-workpiece yokufakela ukuqina kobunzima, okuya kuvelisa i-vibration kunye nesandi esingaqhelekanga, ngeli xesha kufuneka kukhawulezise isantya kunye nesantya sokutya.

5. Ubude bokumiswa komsiki kufuneka bufutshane kangangoko kunokwenzeka.

6. Itafile ephezulu isekelwe kwixabiso lereferensi yokusika kwecala.Iimeko zokusika ze-slot milling zisekelwe kwi-70% yesantya sokusika kwitheyibhile engentla kunye ne-50% yesantya sokutya.

1. Nceda usebenzise izixhobo zomatshini ezichanekileyo kunye nezibambo zesixhobo.

2. Kucelwa usebenzise ukupholisa umoya okanye ulwelo lokusika olungakwaziyo ukuvelisa umsi.

3. Ukusika okugudileyo kunconywa ukusika kwecala.

4. Xa u-rigidity wofakelo lwesixhobo somatshini singasebenzi, ukungcangcazela kunye nesandi esingaqhelekanga singenzeka.Kule nto

ixesha, isantya kunye nesantya feed kule theyibhile ingentla kufuneka kuncitshiswe unyaka nonyaka.

5. Ubude bokumiswa komsiki kufuneka bufutshane kangangoko kunokwenzeka.