OEM 65 ° intsimbi yokusila cutter tungsten intsimbi eqinile ingxubevange 4 Flutes impumlo engqukuva R edge

Uyilo olulodwa olunje

Isicelo

Ilungele ukusetyenzwa kwecala, ukusetyenzwa kwenyathelo, ukusetyenzwa kwe-engile ye-groove.Ine-ALTIN yokwambathisa, ilungele kakhulu ukusetyenzwa kwentsimbi ye-carbon, i-alloy iron, intsimbi etyhidiweyo, i-ductile iron, intsimbi eqiniweyo ngaphambili, intsimbi ecinyiweyo (~ 40/50/55HRC), ingasetyenziselwa ukusetyenzwa kwensimbi engenasici, i-titanium alloy, kunye ingxubevange yokumelana nobushushu.

Iinkcukacha

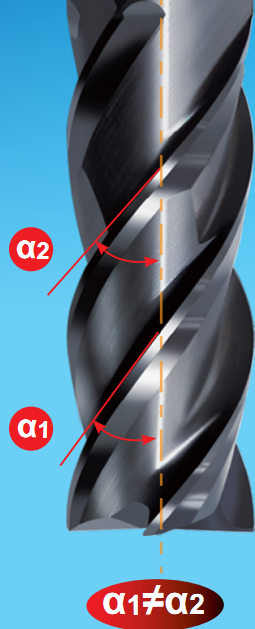

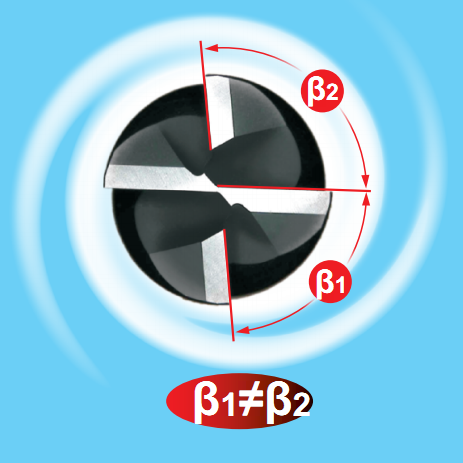

Le mveliso iza kwiinkcukacha ezininzi kunye neemodeli, ezinefluti ezi-4 kunye nee-engile ezimbini ze-helix ze-37 ° kunye ne-40 °.

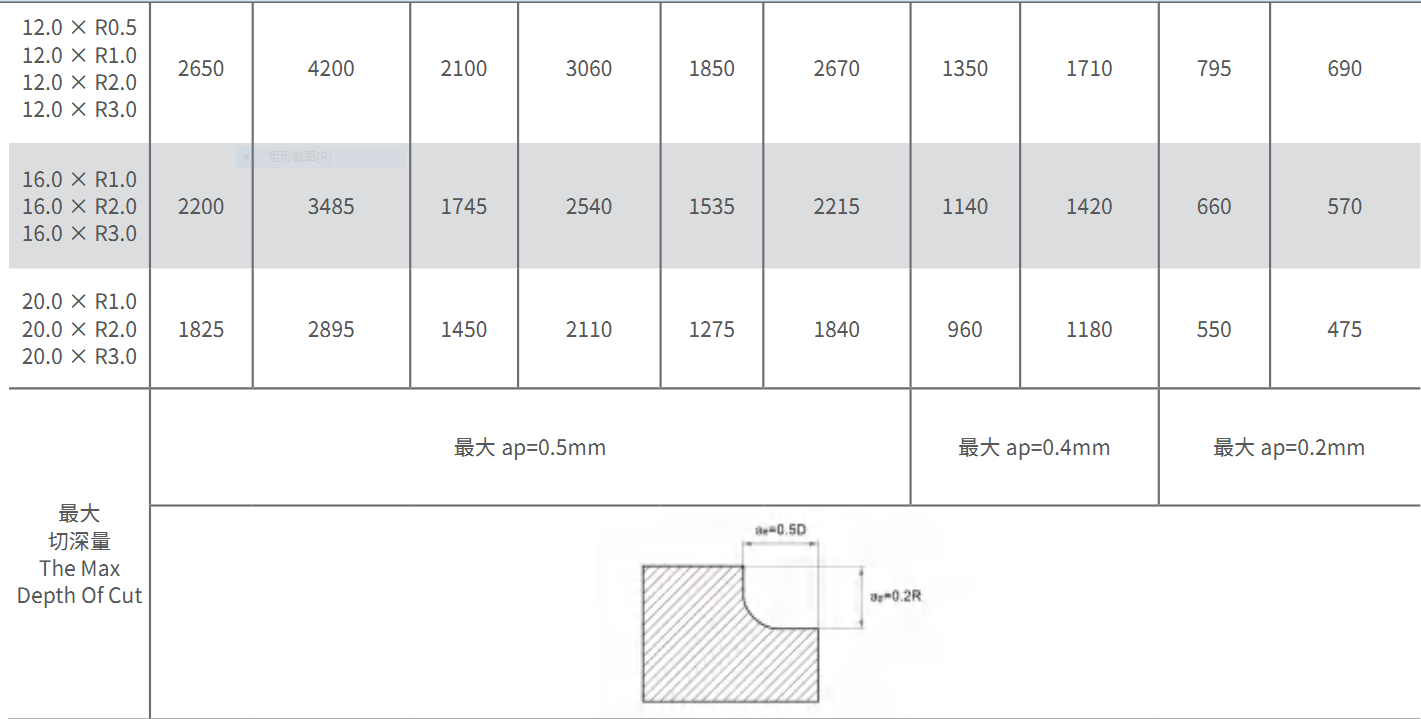

Iiparamitha zokusika ze-ZBM4FR

1, Phantsi kweemeko eziqhelekileyo

1. Le theyibhile ingentla lixabiso eliqhelekileyo le-side iron machining.Xa usenza i-grooves ngesixhobo, isantya sokujikeleza kufuneka sibe yi-50-70% yetafile engentla, kwaye isantya sokutya kufuneka sibe yi-40-60% njengexabiso eliqhelekileyo.

2. Nceda usebenzise izixhobo zomatshini ezichanekileyo kunye nezibambo zesixhobo.

3. Nceda usebenzise ukupholisa umoya okanye ulwelo lokusika olungakwaziyo ukuvelisa umsi.

4. Ukusika okugudileyo kunconywa ukusika kwecala.

5. Xa u-rigidity wofakelo lwesixhobo somatshini singasebenzi kakuhle, ukungcangcazela kunye nesandi esingaqhelekanga singenzeka.Ngeli xesha, isantya kunye nesantya sokutya kwitheyibhile engentla kufuneka sincitshiswe unyaka nonyaka.

6. Ubude bokumiswa komsiki kufuneka bufutshane kangangoko kunokwenzeka.

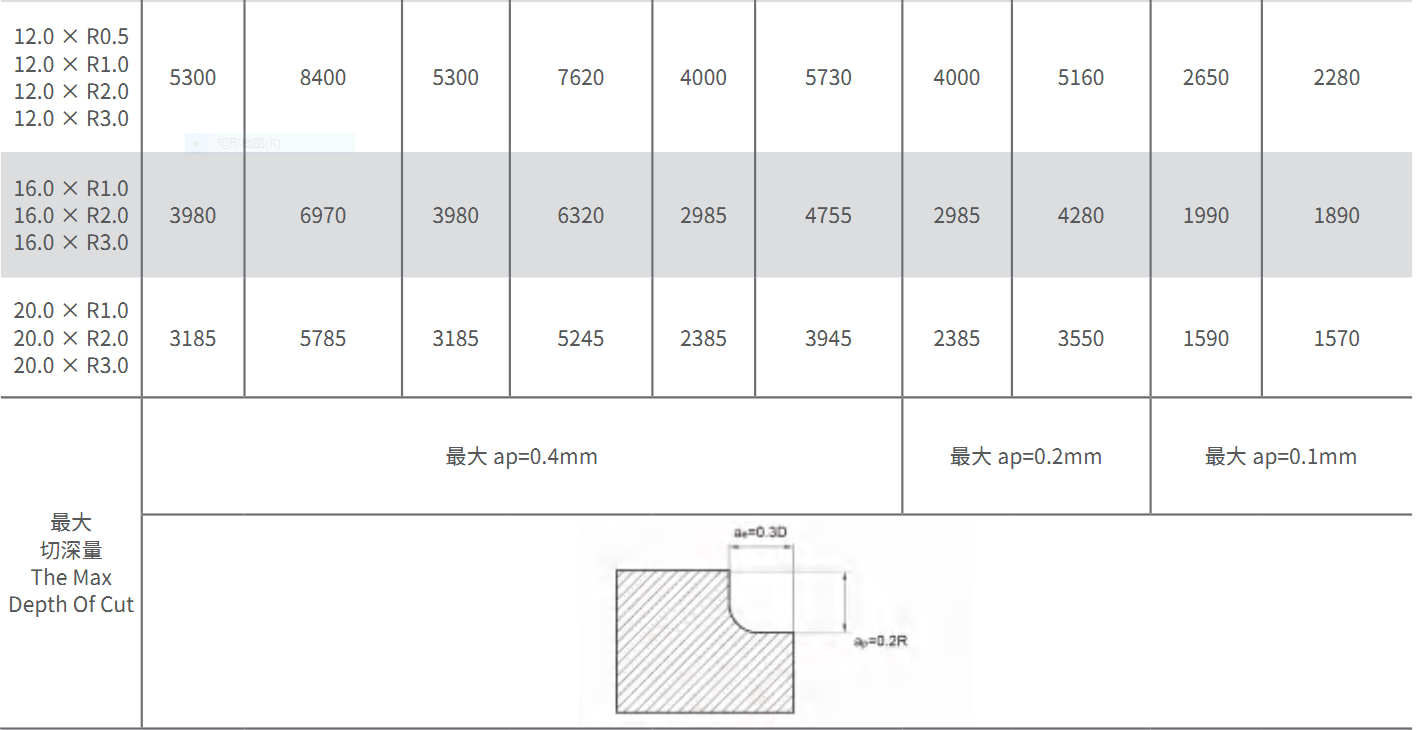

2. Phantsi kweemeko zesantya esiphezulu

1. Le theyibhile ingentla lixabiso eliqhelekileyo le-side iron machining.Xa usenza i-grooves ngesixhobo, isantya sokujikeleza kufuneka sibe yi-50-70% yetafile engentla, kwaye isantya sokutya kufuneka sibe yi-40-60% njengexabiso eliqhelekileyo.

2. Nceda usebenzise izixhobo zomatshini ezichanekileyo kunye nezibambo zesixhobo.

3. Nceda usebenzise ukupholisa umoya okanye ulwelo lokusika olungakwaziyo ukuvelisa umsi.

4. Ukusika okugudileyo kunconywa ukusika kwecala.

5. Xa u-rigidity wofakelo lwesixhobo somatshini singasebenzi kakuhle, ukungcangcazela kunye nesandi esingaqhelekanga singenzeka.Ngeli xesha, isantya kunye nesantya sokutya kwitheyibhile engentla kufuneka sincitshiswe unyaka nonyaka.

6. Ubude bokumiswa komsiki kufuneka bufutshane kangangoko kunokwenzeka.